Materials testing

For 30 years, our teams have gained extensive experience in evaluating materials resistance to the effects of radiation and temperature in a space environment, as well as in high radiation environments: nuclear, medical, etc.

As each project is specific, our radiation engineers specialized in materials, assist you to define the type of test to be carried out and set up a suitable irradiation test plan.

For spatial applications, depending on the exposure of the material to the radiation environment, an irradiation sequence composed of various particles – electrons, protons, neutrons, photons – and various energies may be necessary to be the most representative of the dose profile in orbit.

For nuclear applications, the high radiation levels to which the systems are exposed can be reproduced by testing at high dose rates.

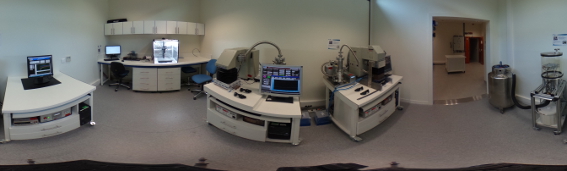

TRAD owns a complete range of means to meet all your requests for testing and qualification:

- Optical microscope, SEM & Xray analysis, optical measurements – transmission and reflectivity / absorptivity – electrical measurements (voltage tests and insulation resistance) and mechanical tests,

- UV aging – up to 15 suns,

- Thermal cycling in vacuum (-180 ° C to + 200 ° C) or atmospheric (-180 ° C to + 400 ° C).

TRAD also has privileged access to other irradiation sites, which may be necessary depending on your test plan requirements (type of particles, associated energy, etc.)

Examples of frequently tested materials:

We test all the materials needed to build a satellite, including coatings, paints, solar cells, optics, cables, harnesses, MLI, coverglasses, OSR, etc.

We also test materials more specific to nuclear applications: joints, polymers, lubricants, etc.